Premier league liverpool crown paints jersey

Van Persie had two nice probabilities to score but was denied by Arsenal keeper Wojciech Szczęsny. Napoli lost the second place because of the defeat suffered on the highway in opposition to Palermo by 2-1. After just two minutes they had been up by one goal due to a penalty kick scored by Cavani, but the home group came from behind to win the game with objectives from Balzaretti and Bovo, which leaves Napoli in third place with sixty five points. Liverpool followers will relish the opportunity tour the renowned Anfield which is rich in heritage and success, get to finish that famous stroll within the footsteps of your heroes as you expertise the journey from the home dressing room out on to the pitch remembering to touch the that is Anfield sign in your approach past. On 27 October 2019, Papastathopoulos – marking his 50th look – scored his first objective of the season, after Crystal Palace failed to clear Nicolas Pépé’s corner in a 2-2 draw at home.

Papastathopoulos seemed to be offside as Guerreiro swung in a free-kick from the precise, which the Greece defender met with a header planted inside the precise-hand publish. The Norway Submit. NRK. Senderos ultimately fell out of favour with Arsenal manager Arsène Wenger. Senderos was given the captain’s armband by supervisor Wilmer Cabrera within the second leg of Houston’s semi-final matchup away to the Portland Timbers, which Houston won 2-1 to advance to the Western Convention Finals. Bernardo Silva scored a first-half brace and Manuel Akanji and Julián Álvarez additional extended their lead in the second half. Both players would, in concept, compete with the incoming Haaland and Álvarez for enjoying time in the event that they remained. Senderos signed for Arsenal in December 2002, although he remained working at Servette until the next summer time. Brookman, man city jerseys – https://www.mailloten.com/product-category/premier-league/manchester-city/ – Derek (10 December 2015). “Draw with Molde not sufficient for Ajax”. Amazingly we will see the sticky tags on the roads and all around the sitting places within the soccer stadium. The huge variety of fans of varied groups will be witnessed by the truth that when video games are being performed, enormous roars are echoed in favor of the teams.

In case you are looking for Manchester Lettings, then undoubtedly you could be spoilt for selections and find yourself on cross roads as finding apt place to live in by yourself could be very time consuming and intimidating. The Rossoneri have seventy four points and get pleasure from of an eight level lead over the defending champions Inter that are available in second place. Later in the season, on 3 February 2007, he was sent off for the second time, a straight pink card for a foul within the penalty field on Middlesbrough striker Yakubu. In the course of the season, Arsenal went undefeated and gained the league. The next yr, a fourth-place league end gave the club a berth in the UEFA Cup for the primary time. Coach Roberto Mancini did pay attention to the followers current at the Etihad Stadium this past Sunday that claimed to see their new star on the pitch, fulfilling their requests on the 60th minute, just three minutes after Bosnian Edin Dzeko gave them the 1-zero lead. The Greek centre back picked up the damage throughout Dortmund’s 1-zero win towards Bayer Leverkusen and was replaced 13 minutes from time on the BayArena.

In these three games, AEK managed one win (the well-known 1-0 victory over A.C. Papastathopoulos joined AEK Athens from Apollon Petalidiou after being scouted by Toni Savevski. Throughout Tuchel’s tenure, Papastathopoulos was promoted to be companion-in-chief to Mats Hummels over Neven Subotic. On 27 July 2002, Senderos scored a brace (and his first aim) in a 2-zero win over Luzern. During the subsequent sport Senderos got a brace to steer Houston to a 3-0 win over Minnesota United. On 5 August 2017, as the captain of the club, he misplaced the 2017 DFL-Supercup on penalties’ recreation in opposition to Bayern Munich. The other two defenders included Mats Hummels of Bayern Munich and Jonathan Tah of Bayer Leverkusen. On 29 November 2006, Senderos was sent off for the first time in his career, within the 66th minute of Arsenal’s 2-1 loss at Fulham for 2 bookings for offences on Luís Boa Morte. On 12 August 2018, he made his official debut with the membership as a starter at Emirates Stadium, in a 2-zero loss against champions Manchester City. 13 March within the 3-zero away victory over Bulgarian champions Ludogorets Razgrad in the first leg of the round of 16 of the UEFA Europa League.

If you liked this article and you would such as to obtain more info relating to arsenal jerseys kindly see our own web site.

On 7 December Arsenal bounced again as they hammered BATE Borisov 6-zero in the ultimate Europa League group stage match with objectives by Mathieu Debuchy, Theo Walcott, Jack Wilshere, Olivier Giroud and Mohamed Elneny in addition to an own purpose by one of many BATE Borisov players. Milan took the lead on 35 minutes but Arsenal went on to win 3-1 with goals by Danny Welbeck and Granit Xhaka with the former scoring a brace. October began with a narrow win over Hungarians MOL Vidi in the Europa League, with Morata scoring the sport’s only aim with twenty minutes to play. Nevertheless, Arsenal’s kind slipped as August began to end. Booth, Martin (24 August 2003). “Wenger: Title is high priority”. Hall, Chris (10 August 2014). “Arsene Wenger buoyant after ‘full performance'”. Despite successful the sport not all the pieces was optimistic for Actual Madrid as they misplaced their prime scorer Ronaldo for the subsequent recreation as a consequence of damage.

On 7 December Arsenal bounced again as they hammered BATE Borisov 6-zero in the ultimate Europa League group stage match with objectives by Mathieu Debuchy, Theo Walcott, Jack Wilshere, Olivier Giroud and Mohamed Elneny in addition to an own purpose by one of many BATE Borisov players. Milan took the lead on 35 minutes but Arsenal went on to win 3-1 with goals by Danny Welbeck and Granit Xhaka with the former scoring a brace. October began with a narrow win over Hungarians MOL Vidi in the Europa League, with Morata scoring the sport’s only aim with twenty minutes to play. Nevertheless, Arsenal’s kind slipped as August began to end. Booth, Martin (24 August 2003). “Wenger: Title is high priority”. Hall, Chris (10 August 2014). “Arsene Wenger buoyant after ‘full performance'”. Despite successful the sport not all the pieces was optimistic for Actual Madrid as they misplaced their prime scorer Ronaldo for the subsequent recreation as a consequence of damage. The report regarded to be extended when Jamie Vardy and Shinji Okazaki scored for the Foxes after a document equaling 94th-second opener from new signing Lacazette, opening his league debut along with his first aggressive Arsenal purpose with only his second contact of the game. Three days later Arsenal performed in the League Cup third round in opposition to League One team Doncaster Rovers at the Emirates. The Gunners topped the group and would go on to face Swedish workforce Östersund within the spherical of 32 of the Europa League which can be held in February. On 17 September Arsenal resumed the Premier League marketing campaign as they played towards champions Chelsea at Stamford Bridge. Arsenal who had been the defending champions of the competitors had been anticipated to win this tie comfortably in opposition to a group whom they hammered in the League Cup final season nevertheless it turned out that the match was an enormous killing: Arsenal were humiliated 4-2 by the Championship workforce and have been knocked out of the FA Cup third round for the first time below Arsène Wenger. Nonetheless, they gained just three factors from their next eight video games, which included a four-match run of defeats and did not embrace a single win, which left Arsenal’s title hopes wanting useless by the turn of 1993. Nevertheless, they were nonetheless within the Football League Cup, and now had the FA Cup to play for.

The report regarded to be extended when Jamie Vardy and Shinji Okazaki scored for the Foxes after a document equaling 94th-second opener from new signing Lacazette, opening his league debut along with his first aggressive Arsenal purpose with only his second contact of the game. Three days later Arsenal performed in the League Cup third round in opposition to League One team Doncaster Rovers at the Emirates. The Gunners topped the group and would go on to face Swedish workforce Östersund within the spherical of 32 of the Europa League which can be held in February. On 17 September Arsenal resumed the Premier League marketing campaign as they played towards champions Chelsea at Stamford Bridge. Arsenal who had been the defending champions of the competitors had been anticipated to win this tie comfortably in opposition to a group whom they hammered in the League Cup final season nevertheless it turned out that the match was an enormous killing: Arsenal were humiliated 4-2 by the Championship workforce and have been knocked out of the FA Cup third round for the first time below Arsène Wenger. Nonetheless, they gained just three factors from their next eight video games, which included a four-match run of defeats and did not embrace a single win, which left Arsenal’s title hopes wanting useless by the turn of 1993. Nevertheless, they were nonetheless within the Football League Cup, and now had the FA Cup to play for.

Antonio Valencia gave the guests an early 4th-minute lead then, solely 7 minutes later, Jesse Lingard made it 2-0. The Gunners tried to take a purpose back before half-time as they dominated much of the first half however United goalkeeper David de Gea produced an excellent performance to cease them doing this. The match was slow and had few shots on target from both side, although United ran out 2-0 winners, with each objectives coming in the first half. The Gunners received 2-zero with Lacazette scoring both objectives. The Gunners won 1-0 with Olivier Giroud scoring an distinctive overhead kick. Arsenal received the match 5-1 with Mkhitaryan bagging three assists, Aaron Ramsey scoring a hat-trick and Aubameyang scoring one. They took the trip to Belarus and won 4-2 against BATE Borisov. His twelfth title, within the 2010-eleven season, was United’s nineteenth overall, overtaking Liverpool’s file of 18. Ferguson received his thirteenth and closing league title in the 2012-13 season, making 20 titles general for United. To make the method simpler and quicker, Simply Jobs confirm each employee registered on their webpage making your job search so much simpler.

Antonio Valencia gave the guests an early 4th-minute lead then, solely 7 minutes later, Jesse Lingard made it 2-0. The Gunners tried to take a purpose back before half-time as they dominated much of the first half however United goalkeeper David de Gea produced an excellent performance to cease them doing this. The match was slow and had few shots on target from both side, although United ran out 2-0 winners, with each objectives coming in the first half. The Gunners received 2-zero with Lacazette scoring both objectives. The Gunners won 1-0 with Olivier Giroud scoring an distinctive overhead kick. Arsenal received the match 5-1 with Mkhitaryan bagging three assists, Aaron Ramsey scoring a hat-trick and Aubameyang scoring one. They took the trip to Belarus and won 4-2 against BATE Borisov. His twelfth title, within the 2010-eleven season, was United’s nineteenth overall, overtaking Liverpool’s file of 18. Ferguson received his thirteenth and closing league title in the 2012-13 season, making 20 titles general for United. To make the method simpler and quicker, Simply Jobs confirm each employee registered on their webpage making your job search so much simpler. Wright scored three league goals for Arsenal on his league debut, away to Southampton. It was a moment of pure and easy magic from Whiteside as he scored the one goal of the match bringing FA Cup glory to the Old Trafford membership as soon as again. Since the second our current financial disaster was launched, the press has completed an admirable job of making sure no person can actually perceive what the heck is occurring. Helping the riffraff actually understand what its authorities and the hidden committees who hand government its orders are doing is definitely NOT a part of the position of the trendy press. It’s doing its job well. Control the public’s attention and direct it to the place you want it to go, which is AWAY from what you are actually doing. Auger had first come to the attention of Finnerty while taking part in a solitary season (2014-15) with the Fife Flyers.

Wright scored three league goals for Arsenal on his league debut, away to Southampton. It was a moment of pure and easy magic from Whiteside as he scored the one goal of the match bringing FA Cup glory to the Old Trafford membership as soon as again. Since the second our current financial disaster was launched, the press has completed an admirable job of making sure no person can actually perceive what the heck is occurring. Helping the riffraff actually understand what its authorities and the hidden committees who hand government its orders are doing is definitely NOT a part of the position of the trendy press. It’s doing its job well. Control the public’s attention and direct it to the place you want it to go, which is AWAY from what you are actually doing. Auger had first come to the attention of Finnerty while taking part in a solitary season (2014-15) with the Fife Flyers.

Completely different skin varieties have totally different wants, and if you have browsed the pores and skin care aisle at the shop currently, you realize there are products accessible for every type of pores and skin. Yet as fanaticism spreads, there is no sign of leadership from the federal government of Pakistan. Folks should be PREVENTED from getting a transparent take a look at our present monetary disaster lest, God forbid, they penetrate the whopping nice hoax the banking sector and their tame authorities have cooked up between them. Although these teams haven’t acquired fissile material they’ve sufficient physics to fabricate a crude bomb past soiled bomb. In an analogous expression of concern Mr M K Narayanan,the former National Safety Adviser (now Governor of West Bengal) had instructed the Individuals that India had come upon cases of manifest attempts by the jihadi outfits to get hold of fissile materials to make a crude nuclear bomb to be used in a terroristic operation. But India hitherto persistently refused to talk in public about any risk of any Indian city being the target of a crude nuclear bomb attack in a terrorist operation, ostensibly for fear of creating panic among the many Indian people, especially when cross border terrorist infiltration is a typical incidence.

Completely different skin varieties have totally different wants, and if you have browsed the pores and skin care aisle at the shop currently, you realize there are products accessible for every type of pores and skin. Yet as fanaticism spreads, there is no sign of leadership from the federal government of Pakistan. Folks should be PREVENTED from getting a transparent take a look at our present monetary disaster lest, God forbid, they penetrate the whopping nice hoax the banking sector and their tame authorities have cooked up between them. Although these teams haven’t acquired fissile material they’ve sufficient physics to fabricate a crude bomb past soiled bomb. In an analogous expression of concern Mr M K Narayanan,the former National Safety Adviser (now Governor of West Bengal) had instructed the Individuals that India had come upon cases of manifest attempts by the jihadi outfits to get hold of fissile materials to make a crude nuclear bomb to be used in a terroristic operation. But India hitherto persistently refused to talk in public about any risk of any Indian city being the target of a crude nuclear bomb attack in a terrorist operation, ostensibly for fear of creating panic among the many Indian people, especially when cross border terrorist infiltration is a typical incidence.

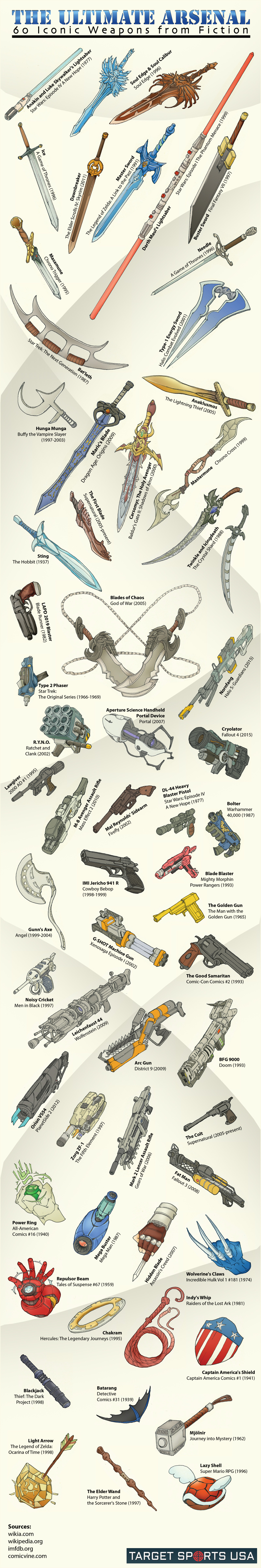

Within the restore part additionally it stood just behind the Kasersky product, and in usability it adopted ESET Internet Security. Amidst the evolving Web threats, when Internet fraudsters are experimenting ploy to get perception of your personal information, and information theft and privacy invasion are making information on world stage, it has grow to be important to offer heed to pc security. Imagine it or not it’s a advertising battle on the market and if you can’t get this accomplished now, someone else will. Which software program to put in and the right way to get these configured? Apart from this, just a few further options like antispam, two-method firewall, parental control, file shredder and file encryption are making look within the Internet safety software. In case you are wandering as what are really within the arsenal of Bitdefender in the present edition then you are on the simply web page, it would make you wade through the vendors declare, specialists opinion and the report launched by varied software program testing firms.

Within the restore part additionally it stood just behind the Kasersky product, and in usability it adopted ESET Internet Security. Amidst the evolving Web threats, when Internet fraudsters are experimenting ploy to get perception of your personal information, and information theft and privacy invasion are making information on world stage, it has grow to be important to offer heed to pc security. Imagine it or not it’s a advertising battle on the market and if you can’t get this accomplished now, someone else will. Which software program to put in and the right way to get these configured? Apart from this, just a few further options like antispam, two-method firewall, parental control, file shredder and file encryption are making look within the Internet safety software. In case you are wandering as what are really within the arsenal of Bitdefender in the present edition then you are on the simply web page, it would make you wade through the vendors declare, specialists opinion and the report launched by varied software program testing firms.

You’ll have nothing but a smooth and steady online experience of any soccer match you prefer to to observe. If you have a cable or broadband speed faster than this one then certainly you may have a terrific free viewing expertise. Because of the advancing technology we’ve got these days, the video high quality of the dwell streams is greatly increased whereas lowering the accessibility complexity of this service. While skates do not necessarily need to be model-new, they should not be damaged in to the purpose the place they supply little or no support. To win bets in fotbollsspel you ought to have the current updates. Christian Eriksen pulled one again in the primary half, before Casemiro and Bruno Fernandes secured the comeback win with a aim each either side of a second-half crimson card for Forest’s Joe Worrall. What’s the last word purpose? 5 days later, Vinícius scored his crew’s objective within the 1-1 home draw of the Champions League second leg against RB Leipzig, prevailing Madrid to the quarter-finals. After a slim 2-1 residence victory over Villarreal on 16 July, thanks to a brace from Benzema, Madrid mathematically clinched a file-extending 34th league title. Lincoln – That is the home to one of the best cathedrals in UK.

You’ll have nothing but a smooth and steady online experience of any soccer match you prefer to to observe. If you have a cable or broadband speed faster than this one then certainly you may have a terrific free viewing expertise. Because of the advancing technology we’ve got these days, the video high quality of the dwell streams is greatly increased whereas lowering the accessibility complexity of this service. While skates do not necessarily need to be model-new, they should not be damaged in to the purpose the place they supply little or no support. To win bets in fotbollsspel you ought to have the current updates. Christian Eriksen pulled one again in the primary half, before Casemiro and Bruno Fernandes secured the comeback win with a aim each either side of a second-half crimson card for Forest’s Joe Worrall. What’s the last word purpose? 5 days later, Vinícius scored his crew’s objective within the 1-1 home draw of the Champions League second leg against RB Leipzig, prevailing Madrid to the quarter-finals. After a slim 2-1 residence victory over Villarreal on 16 July, thanks to a brace from Benzema, Madrid mathematically clinched a file-extending 34th league title. Lincoln – That is the home to one of the best cathedrals in UK. Hence, if you are the soccer addict fan of certainly one of the preferred teams like United Manchester and Liverpool then this could also be a significant pain. That was because the Manchester City teams prior to now have established the unique tradition of all the time carrying this crest on their shirts when taking part in at Wembley (or in a major cup remaining elsewhere) as a logo of their pride in representing town of Manchester at a major sporting event. The draw back of this service is when you’ve got a poor internet connection or if you reside in a rustic with poor web networking and obsolete web speeds of less than 1 MB. Generally feel warmth, such as the British,German World War II, and very humorous sometimes, usually emerge reasonably abruptly a half-day sentence to the people joyful, typically it is vitally Philosophy, typically remark typically very acidic, customers have nicknamed wet individuals He discovered some from the World Cup of rationalization, and a few I have heard some not heard. Another fashionable trend nowadays are the so-known as fan zones wherein tens of millions of individuals get to see soccer dwell on the massive screens which might be set up in strategic areas. There have been no fatalities, but 212 people have been injured.

Hence, if you are the soccer addict fan of certainly one of the preferred teams like United Manchester and Liverpool then this could also be a significant pain. That was because the Manchester City teams prior to now have established the unique tradition of all the time carrying this crest on their shirts when taking part in at Wembley (or in a major cup remaining elsewhere) as a logo of their pride in representing town of Manchester at a major sporting event. The draw back of this service is when you’ve got a poor internet connection or if you reside in a rustic with poor web networking and obsolete web speeds of less than 1 MB. Generally feel warmth, such as the British,German World War II, and very humorous sometimes, usually emerge reasonably abruptly a half-day sentence to the people joyful, typically it is vitally Philosophy, typically remark typically very acidic, customers have nicknamed wet individuals He discovered some from the World Cup of rationalization, and a few I have heard some not heard. Another fashionable trend nowadays are the so-known as fan zones wherein tens of millions of individuals get to see soccer dwell on the massive screens which might be set up in strategic areas. There have been no fatalities, but 212 people have been injured..jpg/1200px-Chelsea_2_Arsenal_0_(20944276374).jpg)

The participant will sign a contract for the following six seasons and the buyout clause is set at €400 million. Who is this participant? The higher class, particularly those that owned factories, saw incredible progress in their wealth. Moreover, the match saw official debuts from Arthur, Lenglet, and Arturo Vidal. Luis Suárez (2), Neymar Jr, Leo Messi and Ivan Rakitic had been on goal, plus one own aim; Aleix Vidal suffered a very critical ankle harm late in the sport. Third place Valencia suffered a resounding 4-0 defeat at Zaragoza this weekend, with goals from Jarosik and Herrera in the first half, and Gabi twice in the second one. On 14 February, Barcelona misplaced 4-0 against Paris Saint-Germain in the primary leg of the primary knockout spherical of the Champions League. On eight March, Barça got here again from a 4-zero deficit in the first leg. On 19 March, Barcelona gained 4-2 towards Valencia, with objectives from Suárez, André Gomes and a brace from Messi.

The participant will sign a contract for the following six seasons and the buyout clause is set at €400 million. Who is this participant? The higher class, particularly those that owned factories, saw incredible progress in their wealth. Moreover, the match saw official debuts from Arthur, Lenglet, and Arturo Vidal. Luis Suárez (2), Neymar Jr, Leo Messi and Ivan Rakitic had been on goal, plus one own aim; Aleix Vidal suffered a very critical ankle harm late in the sport. Third place Valencia suffered a resounding 4-0 defeat at Zaragoza this weekend, with goals from Jarosik and Herrera in the first half, and Gabi twice in the second one. On 14 February, Barcelona misplaced 4-0 against Paris Saint-Germain in the primary leg of the primary knockout spherical of the Champions League. On eight March, Barça got here again from a 4-zero deficit in the first leg. On 19 March, Barcelona gained 4-2 towards Valencia, with objectives from Suárez, André Gomes and a brace from Messi.

It’s used with the current turned off to determine whether a selected electrical element is carrying electricity and to pinpoint the cause of an issue. The going concept was that when the extreme low pressure at the middle of a twister engulfed a home, the higher stress inside would trigger it to explode from within. Ross Barkley made it three after the break earlier than Abraham’s neat flick teed Havertz up for a simple finish inside the world. Diaby participated in all three group stage matches the team played as a starter. A 3-three draw with Chelsea in the first week of September was described as “outstanding” by Houston after the workforce had recovered from a two-goal half-time deficit. France gained the match 3-1 giving the nation its sixth below-19 title and Diaby his first worldwide honor. The title of late-night comedian Chelsea Handler’s new ebook is Chelsea Chelsea Bang Bang (Grand Central Publishing). The sort of tester is at all times used with the current turned on to find out whether or not there may be present flowing by way of a wire and to check for proper grounding.

It’s used with the current turned off to determine whether a selected electrical element is carrying electricity and to pinpoint the cause of an issue. The going concept was that when the extreme low pressure at the middle of a twister engulfed a home, the higher stress inside would trigger it to explode from within. Ross Barkley made it three after the break earlier than Abraham’s neat flick teed Havertz up for a simple finish inside the world. Diaby participated in all three group stage matches the team played as a starter. A 3-three draw with Chelsea in the first week of September was described as “outstanding” by Houston after the workforce had recovered from a two-goal half-time deficit. France gained the match 3-1 giving the nation its sixth below-19 title and Diaby his first worldwide honor. The title of late-night comedian Chelsea Handler’s new ebook is Chelsea Chelsea Bang Bang (Grand Central Publishing). The sort of tester is at all times used with the current turned on to find out whether or not there may be present flowing by way of a wire and to check for proper grounding.

Despite the dominant geo-strategic location, India refrained from demonstrating and unveiling its proactive maritime diplomacy to project power with an goal of securing vital nationwide pursuits. Meanwhile, Harsh V Pant, Professor of International Relations at King’s Faculty, London and Head of Strategic Research at the Observer Analysis Foundation attributed that, “Indian overseas policy is in a candy spot lately. Wooed by main powers of all hues, it may afford to work with everyone, even when at occasions the pulls and pressures seem contradictory. This was even mirrored at this Howdy Modi Event and the G20 summit as effectively in Buenos Aires in December 2018 where the National Capital of India managed to pull off two seemingly contradictory trilaterals. During that time, Narendra Modi met with Donald Trump and Japanese PM Shinzo Abe to underscore India’s agency commitment to make the Indo-Pacific a region for shared financial development, prosperity and safety”, The Professor attributed. Sydney Barnes was plucked from obscurity to affix the England nationwide team and dominate Australia in his first game in Sydney. The Occasions. Retrieved 26 October 2022. The compensation value to Chelsea is understood to be £20 million for their new head coach Potter and an additional £2 million for the 5-sturdy backroom group that have gone with him.

Despite the dominant geo-strategic location, India refrained from demonstrating and unveiling its proactive maritime diplomacy to project power with an goal of securing vital nationwide pursuits. Meanwhile, Harsh V Pant, Professor of International Relations at King’s Faculty, London and Head of Strategic Research at the Observer Analysis Foundation attributed that, “Indian overseas policy is in a candy spot lately. Wooed by main powers of all hues, it may afford to work with everyone, even when at occasions the pulls and pressures seem contradictory. This was even mirrored at this Howdy Modi Event and the G20 summit as effectively in Buenos Aires in December 2018 where the National Capital of India managed to pull off two seemingly contradictory trilaterals. During that time, Narendra Modi met with Donald Trump and Japanese PM Shinzo Abe to underscore India’s agency commitment to make the Indo-Pacific a region for shared financial development, prosperity and safety”, The Professor attributed. Sydney Barnes was plucked from obscurity to affix the England nationwide team and dominate Australia in his first game in Sydney. The Occasions. Retrieved 26 October 2022. The compensation value to Chelsea is understood to be £20 million for their new head coach Potter and an additional £2 million for the 5-sturdy backroom group that have gone with him. However, Chelsea dropped their first points of the marketing campaign towards a West Ham workforce that had been winless at dwelling to date that season. Chelsea and England midfielder Frank Lampard has did not recuperate from a thigh harm that has dominated him out of Euro 2012 and has came a nightmare for new coach Roy Hodgson. Because it got here nearer, the darkness behind me went farther closing in as a small, black ball. The new constituency got here into effect at the 1918 general election. Here, The ‘world group’ witnessed that how Indian PM was welcomed and appreciated by top-up leaders of the US from Jam-Packed Stadium to United state common assembly (UNGA) at giant. Addressing the 74th session of the UN Basic Assembly, PM Narendra Modi exhorted the international community to stand united against terrorism, which he pointed out as considered one of the highest challenges not for any single nation, but for all the world.

However, Chelsea dropped their first points of the marketing campaign towards a West Ham workforce that had been winless at dwelling to date that season. Chelsea and England midfielder Frank Lampard has did not recuperate from a thigh harm that has dominated him out of Euro 2012 and has came a nightmare for new coach Roy Hodgson. Because it got here nearer, the darkness behind me went farther closing in as a small, black ball. The new constituency got here into effect at the 1918 general election. Here, The ‘world group’ witnessed that how Indian PM was welcomed and appreciated by top-up leaders of the US from Jam-Packed Stadium to United state common assembly (UNGA) at giant. Addressing the 74th session of the UN Basic Assembly, PM Narendra Modi exhorted the international community to stand united against terrorism, which he pointed out as considered one of the highest challenges not for any single nation, but for all the world. No. 2 Arsenal was unable to defeat Blackburn Rovers at residence and tied 0-0, reaching 59 points, but they’ve one game pending that if won might put them again in the combat for the title. The muscle is the proof – the justification – that the torture, which have been value many hours in the gym – the sign that you’ve won with your coaching and build extra muscle might. Despite its shortcomings, The Evil Within is nicely worth seeking out if you’re a fan of Mikami’s earlier work or action-horror video games usually. Manchester United played Newcastle United at Old Trafford on Boxing Day in what turned out to be a classic. 2023 70,789 Newcastle United vs. 2023 63,503 Juventus vs. 2017 82,104 Juventus vs. On 24 November, Chelsea took on Juventus in a crucial Champions League group stage match. 2009 71,203 Chelsea vs. 2009 81,807 Chelsea vs. 2011 81,807 Manchester United vs. 2011 70,780 Guadalajara vs.

No. 2 Arsenal was unable to defeat Blackburn Rovers at residence and tied 0-0, reaching 59 points, but they’ve one game pending that if won might put them again in the combat for the title. The muscle is the proof – the justification – that the torture, which have been value many hours in the gym – the sign that you’ve won with your coaching and build extra muscle might. Despite its shortcomings, The Evil Within is nicely worth seeking out if you’re a fan of Mikami’s earlier work or action-horror video games usually. Manchester United played Newcastle United at Old Trafford on Boxing Day in what turned out to be a classic. 2023 70,789 Newcastle United vs. 2023 63,503 Juventus vs. 2017 82,104 Juventus vs. On 24 November, Chelsea took on Juventus in a crucial Champions League group stage match. 2009 71,203 Chelsea vs. 2009 81,807 Chelsea vs. 2011 81,807 Manchester United vs. 2011 70,780 Guadalajara vs.

He is a Benin worldwide, having represented the nation at the 2008, 2010 and 2019 editions of the Africa Cup of Nations. A 2-1 win against title challengers Newcastle United, having performed three-quarters of the match with ten males, moved Arsenal again to the top of the desk. The group ended the month joint top of the table with Newcastle United, both on 24 points having performed eleven games. After dealing with an damage within the month of March, he returned to play in April scoring his first purpose for the membership in a 5-0 victory over Aston Villa on April Fools’ Day 2006. He was arrange for the objective by fellow membership newcomer Emmanuel Adebayor. In the first leg, staged at Highbury, Arsenal misplaced Bergkamp by way of harm earlier than the half-hour; the player was replaced by fellow Dutchman Glenn Helder. Moore, Glenn (17 September 1996). “Wenger confirmed as Arsenal supervisor”. Every day Mirror. London. 27 July 1996. p. Attention quickly turned to the North London derby, the place Arsenal confronted Tottenham Hotspur on 24 November 1996. Arsenal had not overwhelmed their neighbours in over three years and Tottenham had been unbeaten at Highbury since September 1991. The match had ramifications within the league: a win probably positioned Arsenal ready to move into first spot, if different results went in their favour.

He is a Benin worldwide, having represented the nation at the 2008, 2010 and 2019 editions of the Africa Cup of Nations. A 2-1 win against title challengers Newcastle United, having performed three-quarters of the match with ten males, moved Arsenal again to the top of the desk. The group ended the month joint top of the table with Newcastle United, both on 24 points having performed eleven games. After dealing with an damage within the month of March, he returned to play in April scoring his first purpose for the membership in a 5-0 victory over Aston Villa on April Fools’ Day 2006. He was arrange for the objective by fellow membership newcomer Emmanuel Adebayor. In the first leg, staged at Highbury, Arsenal misplaced Bergkamp by way of harm earlier than the half-hour; the player was replaced by fellow Dutchman Glenn Helder. Moore, Glenn (17 September 1996). “Wenger confirmed as Arsenal supervisor”. Every day Mirror. London. 27 July 1996. p. Attention quickly turned to the North London derby, the place Arsenal confronted Tottenham Hotspur on 24 November 1996. Arsenal had not overwhelmed their neighbours in over three years and Tottenham had been unbeaten at Highbury since September 1991. The match had ramifications within the league: a win probably positioned Arsenal ready to move into first spot, if different results went in their favour.

The shirt was combined with sky blue shorts for the primary time since the 2006-07 season and with hooped socks. Manchester United also achieved their greatest league position so far, finishing runner-up to Chelsea and qualifying for the UEFA Ladies’s Champions League for the primary time in the method. 21 league video games with no loss from December to April, including 16 victories. Mascall, Roger (18 December 2009). “The Heritage Safety Invoice: Fundamental reform for England and Wales?”. Lashley, Brian (5 Might 2009). “Manchester Central marks milestone”. Army. Some land should still comprise chemical weapons units (equivalent to unexploded projectiles or buried gear) and can’t safely be integrated into the wildlife refuge, so the Fish & Wildlife Service manages 14,904 acres (60.31 km2) of land. Northern Route Utilisation Technique Archived 10 April 2015 at the Wayback Machine, Network Rail, May 2011, web page 7 and pp. The Manchester Metrolink light rail network was extended from St Werburgh’s Highway to Manchester Airport as a part of the Section three growth mission.

The shirt was combined with sky blue shorts for the primary time since the 2006-07 season and with hooped socks. Manchester United also achieved their greatest league position so far, finishing runner-up to Chelsea and qualifying for the UEFA Ladies’s Champions League for the primary time in the method. 21 league video games with no loss from December to April, including 16 victories. Mascall, Roger (18 December 2009). “The Heritage Safety Invoice: Fundamental reform for England and Wales?”. Lashley, Brian (5 Might 2009). “Manchester Central marks milestone”. Army. Some land should still comprise chemical weapons units (equivalent to unexploded projectiles or buried gear) and can’t safely be integrated into the wildlife refuge, so the Fish & Wildlife Service manages 14,904 acres (60.31 km2) of land. Northern Route Utilisation Technique Archived 10 April 2015 at the Wayback Machine, Network Rail, May 2011, web page 7 and pp. The Manchester Metrolink light rail network was extended from St Werburgh’s Highway to Manchester Airport as a part of the Section three growth mission.

His final cap with the nationwide crew was on 2 June 2009 in a friendly match towards Nigeria, and was not included by coach Raymond Domenech in France’s squad for the 2010 World Cup in South Africa. Due to its stability and sheer destructive energy, C-four has attracted the eye of terrorists and guerilla fighters all around the world. C-four has also been used in lots of the Palestinian suicide bombings in Israel and the Israeli-occupied territories. When somebody triggers the detonator (by transmitting the cost by detonator cord to a blasting cap, for instance), the explosion applies a strong shock that triggers the C-four explosive material. Unfortunately, C-four will keep making headlines for years to return. Regardless of your ability level or expertise, these 10 will show, effectively, useful. Robinho will not be needled! When the compound molecules break apart, the products (the ensuing gases) might use a few of this power to kind new bonds, but not all of it. Most of the “leftover” vitality takes the form of excessive heat. This system takes pictures of kids who share a genetic disorder, normally a sequence of 30 to 50, and creates a 3-dimensional composite picture for that disorder. As a control, Hammond additionally fed into his database images of kids and not using a genetic disorder,

His final cap with the nationwide crew was on 2 June 2009 in a friendly match towards Nigeria, and was not included by coach Raymond Domenech in France’s squad for the 2010 World Cup in South Africa. Due to its stability and sheer destructive energy, C-four has attracted the eye of terrorists and guerilla fighters all around the world. C-four has also been used in lots of the Palestinian suicide bombings in Israel and the Israeli-occupied territories. When somebody triggers the detonator (by transmitting the cost by detonator cord to a blasting cap, for instance), the explosion applies a strong shock that triggers the C-four explosive material. Unfortunately, C-four will keep making headlines for years to return. Regardless of your ability level or expertise, these 10 will show, effectively, useful. Robinho will not be needled! When the compound molecules break apart, the products (the ensuing gases) might use a few of this power to kind new bonds, but not all of it. Most of the “leftover” vitality takes the form of excessive heat. This system takes pictures of kids who share a genetic disorder, normally a sequence of 30 to 50, and creates a 3-dimensional composite picture for that disorder. As a control, Hammond additionally fed into his database images of kids and not using a genetic disorder,

Danny Welbeck takes a swipe at a shot after Pascal Gross reaches the byline on the best and cuts the ball back contained in the penalty space. Diogo Dalot concedes a corner on the appropriate after Solly March races on to a crossfield pass and attempts a cross. Solly March is in ache. Christian Eriksen sends an inswinger in direction of the penalty space. Christian Eriksen takes, and it is not a very good supply. Despite surrendering huge swathes of possession to Barcelona, United almost prolonged their lead shortly earlier than half time, Nani heading wide from a great cross from Park Ji-sung. George Graham after Ian Wrights hattrick had demolished the non-league Yeovil Town on their very own patch on the Huish Park. Aaron Wan Bissaka places in a excellent sort out but the ball bobbles into the trail of Enciso, who fires a shot broad. On May 8, 2022, during a Premier League match towards Arsenal, Ayling was despatched off for a two footed sort out on Gabriel Martinelli. By the seems of it, he may not be capable of proceed. That looks a little harsh – but attracts an enormous roar from the Brighton fans. United break as far because the halfway line, where Lewis Dunk intercepts to an enormous roar from the Brighton fans.

Danny Welbeck takes a swipe at a shot after Pascal Gross reaches the byline on the best and cuts the ball back contained in the penalty space. Diogo Dalot concedes a corner on the appropriate after Solly March races on to a crossfield pass and attempts a cross. Solly March is in ache. Christian Eriksen sends an inswinger in direction of the penalty space. Christian Eriksen takes, and it is not a very good supply. Despite surrendering huge swathes of possession to Barcelona, United almost prolonged their lead shortly earlier than half time, Nani heading wide from a great cross from Park Ji-sung. George Graham after Ian Wrights hattrick had demolished the non-league Yeovil Town on their very own patch on the Huish Park. Aaron Wan Bissaka places in a excellent sort out but the ball bobbles into the trail of Enciso, who fires a shot broad. On May 8, 2022, during a Premier League match towards Arsenal, Ayling was despatched off for a two footed sort out on Gabriel Martinelli. By the seems of it, he may not be capable of proceed. That looks a little harsh – but attracts an enormous roar from the Brighton fans. United break as far because the halfway line, where Lewis Dunk intercepts to an enormous roar from the Brighton fans. The effort sails into the Brighton fans behind the goal. Following an international break, the Gunners’ home match in opposition to Sunderland regarded set to be heading for a 1-1 draw until Van Persie scored in the last ten minutes to secure all three points, whilst a late purpose also earned an away European victory in opposition to Marseille,

The effort sails into the Brighton fans behind the goal. Following an international break, the Gunners’ home match in opposition to Sunderland regarded set to be heading for a 1-1 draw until Van Persie scored in the last ten minutes to secure all three points, whilst a late purpose also earned an away European victory in opposition to Marseille,

The coarse elements in exfoliating soap are the physical particles that buff your skin after you remove the useless cells. The coarse particles in exfoliating soap can be too abrasive, and the tingling feeling from acidic components can flip right into a burning sensation when you depart the cleaning soap on longer than the advisable one to 2 minutes. Some individuals use an exfoliating cleaning soap with harsher elements a few times per week, and others choose to make use of an all-in-one gentle exfoliating soap on daily basis. Moisturizing gloves contain quite a lot of components to help your pores and skin, equivalent to oils, vitamins and aloe. AHAs like glycolic acid from sugar, fruit acids or lactic acid (derived from milk) can help construct a brand new layer of easy hydrated skin cells, which may give the looks of healthier skin. Stronger exfoliating soaps include glycolic acid and different chemicals. Even better, exfoliating soaps can work with any pores and skin sort, so whether you may have oily, dry, normal or mixture pores and skin, there’s a product for you. By the ’90s, it was normal for a Premier League player to pull down £10,000 a week.

The coarse elements in exfoliating soap are the physical particles that buff your skin after you remove the useless cells. The coarse particles in exfoliating soap can be too abrasive, and the tingling feeling from acidic components can flip right into a burning sensation when you depart the cleaning soap on longer than the advisable one to 2 minutes. Some individuals use an exfoliating cleaning soap with harsher elements a few times per week, and others choose to make use of an all-in-one gentle exfoliating soap on daily basis. Moisturizing gloves contain quite a lot of components to help your pores and skin, equivalent to oils, vitamins and aloe. AHAs like glycolic acid from sugar, fruit acids or lactic acid (derived from milk) can help construct a brand new layer of easy hydrated skin cells, which may give the looks of healthier skin. Stronger exfoliating soaps include glycolic acid and different chemicals. Even better, exfoliating soaps can work with any pores and skin sort, so whether you may have oily, dry, normal or mixture pores and skin, there’s a product for you. By the ’90s, it was normal for a Premier League player to pull down £10,000 a week.

They led 2-zero within eight minutes in Brighton by Stina Blackstenius. James Tomkins’ header from an Eberechi Eze free kick within the thirty-ninth minute hit the crossbar, while Christian Benteke’s header from a Tyrick Mitchell cross minutes later was parried broad by Bernd Leno. Bernd Leno is anticipated to start in goal for Arsenal. Partey can be making his first start since returning from harm, and his presence in midfield could be key in controlling the sport for Arsenal. While Gabriel Jesus continues his restoration from a knee harm, Reiss Nelson is nursing a significant thigh problem. Aubameyang and Lacazette have been Arsenal’s prime scorers this season with six targets each, whereas Saka’s creativity and versatility may very well be key in unlocking Brighton’s defence. The 23-12 months-previous has been spectacular in his first full season as Brighton’s first-choice goalkeeper, holding six clear sheets in 15 Premier League appearances. The trio have been stable at the again for Brighton this season, but may have their work cut out against an Arsenal side that has scored 20 goals in their last 10 Premier League matches. Brighton will probably be hoping to construct on their current good kind, whereas Arsenal shall be seeking to bounce back from their disappointing defeat to Manchester City.

They led 2-zero within eight minutes in Brighton by Stina Blackstenius. James Tomkins’ header from an Eberechi Eze free kick within the thirty-ninth minute hit the crossbar, while Christian Benteke’s header from a Tyrick Mitchell cross minutes later was parried broad by Bernd Leno. Bernd Leno is anticipated to start in goal for Arsenal. Partey can be making his first start since returning from harm, and his presence in midfield could be key in controlling the sport for Arsenal. While Gabriel Jesus continues his restoration from a knee harm, Reiss Nelson is nursing a significant thigh problem. Aubameyang and Lacazette have been Arsenal’s prime scorers this season with six targets each, whereas Saka’s creativity and versatility may very well be key in unlocking Brighton’s defence. The 23-12 months-previous has been spectacular in his first full season as Brighton’s first-choice goalkeeper, holding six clear sheets in 15 Premier League appearances. The trio have been stable at the again for Brighton this season, but may have their work cut out against an Arsenal side that has scored 20 goals in their last 10 Premier League matches. Brighton will probably be hoping to construct on their current good kind, whereas Arsenal shall be seeking to bounce back from their disappointing defeat to Manchester City. Maupay has been Brighton’s high scorer this season with seven targets, whereas Welbeck will be looking to make an influence in opposition to his former club. Both groups will likely be searching for a win to boost their position in the league desk and acquire some a lot-wanted momentum going into the second half of the season. It guarantees to be an thrilling match, and the starting lineups of each teams counsel that we could be in for a high-scoring affair. Brighton Starting 11 (4-2-3-1): Sanchez; Veltman, Dunk, Colwill, Estupinan; Gross, Gilmour; March, Lallana, Mitoma; Trossard. Arsenal Starting eleven (4-3-3): Ramsdale; White, Saliba, Gabriel, Zinchenko; Odegaard, Partey, Xhaka; Saka, Nketiah, Martinelli. Arteta is predicted to go with a midfield trio of Granit Xhaka, Thomas Partey, and Dani Ceballos. Arteta will point to a a lot-rotated XI that day however De Zerbi rested his high scorer Leandro Trossard as effectively. Brighton’s win over rock-bottom Southampton left them one level off sixth-placed Liverpool after Boxing Day. Leeds also won the fixture at Elland Road 3-2 and became the primary of the 2 sides to realize a double over the other (successful each fixtures between the 2 sides in a single season).

Maupay has been Brighton’s high scorer this season with seven targets, whereas Welbeck will be looking to make an influence in opposition to his former club. Both groups will likely be searching for a win to boost their position in the league desk and acquire some a lot-wanted momentum going into the second half of the season. It guarantees to be an thrilling match, and the starting lineups of each teams counsel that we could be in for a high-scoring affair. Brighton Starting 11 (4-2-3-1): Sanchez; Veltman, Dunk, Colwill, Estupinan; Gross, Gilmour; March, Lallana, Mitoma; Trossard. Arsenal Starting eleven (4-3-3): Ramsdale; White, Saliba, Gabriel, Zinchenko; Odegaard, Partey, Xhaka; Saka, Nketiah, Martinelli. Arteta is predicted to go with a midfield trio of Granit Xhaka, Thomas Partey, and Dani Ceballos. Arteta will point to a a lot-rotated XI that day however De Zerbi rested his high scorer Leandro Trossard as effectively. Brighton’s win over rock-bottom Southampton left them one level off sixth-placed Liverpool after Boxing Day. Leeds also won the fixture at Elland Road 3-2 and became the primary of the 2 sides to realize a double over the other (successful each fixtures between the 2 sides in a single season). He had accomplished 5 seasons as manager with out them finishing exterior the top four and had won two FA Cups, however the look forward to a league title was now getting into its twentieth season. The next day, former United striker Ole Gunnar Solskjær was appointed as caretaker supervisor until the end of the season, assisted by former coach Mike Phelan, who had left the membership in 2013 following the retirement of Sir Alex Ferguson. His first game as supervisor was a 4-0 thrashing of Norwich City at Old Trafford, with Wayne Rooney and Juan Mata every scoring a pair. Before the month had ended, they ensured that their League Cup quest remained alive by beating Portsmouth 3-1 in the third round at Old Trafford. Danny Welbeck could return to face his outdated membership as he nears the conclusion of a muscular harm but Adam Webster and the celebrating Alexis Mac Allister aren’t anticipated until January.

He had accomplished 5 seasons as manager with out them finishing exterior the top four and had won two FA Cups, however the look forward to a league title was now getting into its twentieth season. The next day, former United striker Ole Gunnar Solskjær was appointed as caretaker supervisor until the end of the season, assisted by former coach Mike Phelan, who had left the membership in 2013 following the retirement of Sir Alex Ferguson. His first game as supervisor was a 4-0 thrashing of Norwich City at Old Trafford, with Wayne Rooney and Juan Mata every scoring a pair. Before the month had ended, they ensured that their League Cup quest remained alive by beating Portsmouth 3-1 in the third round at Old Trafford. Danny Welbeck could return to face his outdated membership as he nears the conclusion of a muscular harm but Adam Webster and the celebrating Alexis Mac Allister aren’t anticipated until January.

Notably, this was the primary time Arsenal accomplished the double over Chelsea for the reason that 2003-04 Invincibles season. English soccer has built up debts of around three billion pounds in any respect levels, the English Football accociation reported last year, with practically a third of that owed by the highest four clubs Manchester United, Liverpool, Chelsea and Arsenal. Champions earlier than Leicester, Chelsea are still in a disarray. Their assault of nonetheless very lethal but there defense has been very leaky. Depending upon where a low-yield weapon lands, “it still has city-killing potential,” Kimball says. As Kimball points out, the U.S. S. low-yield capability – which now consists of about 500 gravity bombs that could be dropped by U.S. It’s preliminary operate was to hold nuclear bombs across the globe, take out key targets and escape to security, evading any enemy sensors the whole time. Landmines are one of the horrific weapons of struggle because they proceed to take casualties long after a conflict is resolved. The machine gun is one of those weapons that completely modified the face of the struggle. Flamethrowers are one of the vital fascinating weapons of conflict, if not one in every of the most important. Through the Cold War, the U.S.

Notably, this was the primary time Arsenal accomplished the double over Chelsea for the reason that 2003-04 Invincibles season. English soccer has built up debts of around three billion pounds in any respect levels, the English Football accociation reported last year, with practically a third of that owed by the highest four clubs Manchester United, Liverpool, Chelsea and Arsenal. Champions earlier than Leicester, Chelsea are still in a disarray. Their assault of nonetheless very lethal but there defense has been very leaky. Depending upon where a low-yield weapon lands, “it still has city-killing potential,” Kimball says. As Kimball points out, the U.S. S. low-yield capability – which now consists of about 500 gravity bombs that could be dropped by U.S. It’s preliminary operate was to hold nuclear bombs across the globe, take out key targets and escape to security, evading any enemy sensors the whole time. Landmines are one of the horrific weapons of struggle because they proceed to take casualties long after a conflict is resolved. The machine gun is one of those weapons that completely modified the face of the struggle. Flamethrowers are one of the vital fascinating weapons of conflict, if not one in every of the most important. Through the Cold War, the U.S.

He made his first look of the season towards Ipswich Town within the second round of the League Cup and helped the club win 2-1 to advance to the subsequent round. Therefore, before we start blaming the Football Association, membership Boards, house owners and so forth for bad monetary administration, we would be wise to look at the financial context wherein membership homeowners and their boards are in search of to steadiness their books, compete, survive and hopefully win a few trophies and to seek out out what that “something” is. It’s also unclear whether or not Trump will need to renew New Start. If you utilize them over creams, then it will likely be ineffective as creams shut the pores, preventing ingredients in serum from coming into the layer. Arsenal the standard contenders are proper on playing sensible which they’ll until December but after that they always fall down. Irrespective of which a part of the world you are, you may always choose from a wide range of equipment right at your doorstep. Submarines are actually unique watercraft, and as such, they’re an essential a part of the U.S. For the battlefield of the longer term, the U.S.

He made his first look of the season towards Ipswich Town within the second round of the League Cup and helped the club win 2-1 to advance to the subsequent round. Therefore, before we start blaming the Football Association, membership Boards, house owners and so forth for bad monetary administration, we would be wise to look at the financial context wherein membership homeowners and their boards are in search of to steadiness their books, compete, survive and hopefully win a few trophies and to seek out out what that “something” is. It’s also unclear whether or not Trump will need to renew New Start. If you utilize them over creams, then it will likely be ineffective as creams shut the pores, preventing ingredients in serum from coming into the layer. Arsenal the standard contenders are proper on playing sensible which they’ll until December but after that they always fall down. Irrespective of which a part of the world you are, you may always choose from a wide range of equipment right at your doorstep. Submarines are actually unique watercraft, and as such, they’re an essential a part of the U.S. For the battlefield of the longer term, the U.S.

From these days again in the middle of the last decade to the current day, the club has somewhere lost in the section of transition. The club is nowhere again to the place it was did it the last decade and even after the transition period was overcome successfully by Wenger and the board, the membership has since then didn’t pack a punch in the Premiere League and the Champions League as nicely. The Hammers definitely cannot survive one other interval of the Premier League with Andy Carroll as the principle determination striker. After a horrible week for the Gunners that noticed them humiliated in Milan losing the Serie A facet AC 4-zero due to an inspired performance from their striker star striker Zlatan Ibrahimovic and ending the week with a damp squib of a result against Sunderland shedding 2-zero at the Stadium of Light has left it almost a certainty that the North London club will go a seventh year with out a trophy. Even if it might not precisely be “world class” numbers, it is a respectable aggregate for a Premier League striker given that sixty eight of these appearances have been off the seat. Despite the fixed troubles that have come from zonal marking, Arsenal used this technique from set-items all throughout the game, which ultimately led to Joleon Lescott’s 40th-minute header giving City the lead till Laurent Koscielny’s 82nd-minute equaliser, giving Arsenal a deserved draw at the Etihad.

From these days again in the middle of the last decade to the current day, the club has somewhere lost in the section of transition. The club is nowhere again to the place it was did it the last decade and even after the transition period was overcome successfully by Wenger and the board, the membership has since then didn’t pack a punch in the Premiere League and the Champions League as nicely. The Hammers definitely cannot survive one other interval of the Premier League with Andy Carroll as the principle determination striker. After a horrible week for the Gunners that noticed them humiliated in Milan losing the Serie A facet AC 4-zero due to an inspired performance from their striker star striker Zlatan Ibrahimovic and ending the week with a damp squib of a result against Sunderland shedding 2-zero at the Stadium of Light has left it almost a certainty that the North London club will go a seventh year with out a trophy. Even if it might not precisely be “world class” numbers, it is a respectable aggregate for a Premier League striker given that sixty eight of these appearances have been off the seat. Despite the fixed troubles that have come from zonal marking, Arsenal used this technique from set-items all throughout the game, which ultimately led to Joleon Lescott’s 40th-minute header giving City the lead till Laurent Koscielny’s 82nd-minute equaliser, giving Arsenal a deserved draw at the Etihad.

It was the fifth tie between the two clubs and the primary time they’d confronted each other since 2002 when United received 3-2 in the primary group spherical. However, United had gained a repute for enjoying comparatively dull football beneath Sexton after the extra entertaining fashion of play under Tommy Docherty, and by the end of his third season as manager that they had still but to win a major trophy, as Liverpool received a fifth title in eight seasons. On 20 July, Liverpool gained 2-zero in opposition to Adelaide United with goals from James Milner and Danny Ings. On 2 February, Liverpool travelled to the King Power Stadium to play Leicester City, losing 2-0 through objectives by Jamie Vardy. The ultimate tally of 102 league targets was at the time the second-highest Premier League season whole and one objective short of Chelsea’s 2009-10 document. Although United recorded wins over Premier League giants Arsenal, Liverpool and in-form Southampton, they have been greatly indebted to Spanish goalkeeper David de Gea, who made many sport-saving stops.

It was the fifth tie between the two clubs and the primary time they’d confronted each other since 2002 when United received 3-2 in the primary group spherical. However, United had gained a repute for enjoying comparatively dull football beneath Sexton after the extra entertaining fashion of play under Tommy Docherty, and by the end of his third season as manager that they had still but to win a major trophy, as Liverpool received a fifth title in eight seasons. On 20 July, Liverpool gained 2-zero in opposition to Adelaide United with goals from James Milner and Danny Ings. On 2 February, Liverpool travelled to the King Power Stadium to play Leicester City, losing 2-0 through objectives by Jamie Vardy. The ultimate tally of 102 league targets was at the time the second-highest Premier League season whole and one objective short of Chelsea’s 2009-10 document. Although United recorded wins over Premier League giants Arsenal, Liverpool and in-form Southampton, they have been greatly indebted to Spanish goalkeeper David de Gea, who made many sport-saving stops.

United started brightly, as Rooney set up Antonio Valencia for the game’s opener in the ninth minute, and cemented their lead a few minutes later after two quick-fire objectives from Van Persie and Rooney. And No. 4 Lazio introduced a resounding 1-four victory from their go to to Catania, which represented three extra factors for a complete of 60 that give them a one level lead over Udinese. Despite having fun with a 12 level lead with regard to the No. 2 Bayern Leverkusen, the Bundesliga solo leaders Borussia Dortmund don’t have time to chill out, and so they proved it once again in match day 25 with a 1-zero home win over Colonia. The Gunners are second with 57 points, however have one pending recreation. Ray Parlour rapidly pulled one again. 18 October 2011: Belgian centre again Thomas Vermaelen signs a brand new lengthy-time period contract. The ultimate league match of April noticed Manchester United’s first go to to “Roses” rival Leeds’ Elland Road since October 2003, which ended goalless. Dean, Sam; Bagchi, Rob (31 October 2018). “Arsenal hold off Blackpool’s late surge after Matteo Guendouzi rashly sees red”. Two targets from Sculli in the first half have been enough for them to achieve fifty one points and scale back the gap with Napoli to solely two points.

United started brightly, as Rooney set up Antonio Valencia for the game’s opener in the ninth minute, and cemented their lead a few minutes later after two quick-fire objectives from Van Persie and Rooney. And No. 4 Lazio introduced a resounding 1-four victory from their go to to Catania, which represented three extra factors for a complete of 60 that give them a one level lead over Udinese. Despite having fun with a 12 level lead with regard to the No. 2 Bayern Leverkusen, the Bundesliga solo leaders Borussia Dortmund don’t have time to chill out, and so they proved it once again in match day 25 with a 1-zero home win over Colonia. The Gunners are second with 57 points, however have one pending recreation. Ray Parlour rapidly pulled one again. 18 October 2011: Belgian centre again Thomas Vermaelen signs a brand new lengthy-time period contract. The ultimate league match of April noticed Manchester United’s first go to to “Roses” rival Leeds’ Elland Road since October 2003, which ended goalless. Dean, Sam; Bagchi, Rob (31 October 2018). “Arsenal hold off Blackpool’s late surge after Matteo Guendouzi rashly sees red”. Two targets from Sculli in the first half have been enough for them to achieve fifty one points and scale back the gap with Napoli to solely two points. Despite taking a 38th-minute lead with a low drive from Tomáš Rosický, Arsenal surrendered yet another lead with two goals in beneath 10 minutes from Ioannis Maniatis and Konstantinos Mitroglou to present Olympiacos a 2-1 win. Despite this setback, Arsenal went on to have a robust first half, however faded away within the second half, with only Hector Bellerin’s fierce volley on 68 minutes severely testing the Leicester again line. Milan took the lead on 35 minutes however Arsenal went on to win 3-1 with goals by Danny Welbeck and Granit Xhaka with the former scoring a brace. In August 2022, the result was equalled by Liverpool’s 9-zero win over AFC Bournemouth, the fourth match in Premier League history to be won by such a scoreline. Forty seven consecutive league matches, breaking Chesterfield Town’s achievement. Stoke, however, hit poor kind, dropping 4 in a row in October and have been knocked out of the League Cup by West Ham United. These included West Ham United midfielder Paul Ince, Southampton winger Danny Wallace, Nottingham Forest midfielder Neil Webb and Norwich City midfielder Mike Phelan. Manchester City and Manchester United have to date been probably the most lively with City signing Sergio Aguero from Atletico Madrid and Gael Clichy from Arsenal whereas United have signed Ashley Young from Aston Villa and Jones from Blackburn Rovers.

Despite taking a 38th-minute lead with a low drive from Tomáš Rosický, Arsenal surrendered yet another lead with two goals in beneath 10 minutes from Ioannis Maniatis and Konstantinos Mitroglou to present Olympiacos a 2-1 win. Despite this setback, Arsenal went on to have a robust first half, however faded away within the second half, with only Hector Bellerin’s fierce volley on 68 minutes severely testing the Leicester again line. Milan took the lead on 35 minutes however Arsenal went on to win 3-1 with goals by Danny Welbeck and Granit Xhaka with the former scoring a brace. In August 2022, the result was equalled by Liverpool’s 9-zero win over AFC Bournemouth, the fourth match in Premier League history to be won by such a scoreline. Forty seven consecutive league matches, breaking Chesterfield Town’s achievement. Stoke, however, hit poor kind, dropping 4 in a row in October and have been knocked out of the League Cup by West Ham United. These included West Ham United midfielder Paul Ince, Southampton winger Danny Wallace, Nottingham Forest midfielder Neil Webb and Norwich City midfielder Mike Phelan. Manchester City and Manchester United have to date been probably the most lively with City signing Sergio Aguero from Atletico Madrid and Gael Clichy from Arsenal whereas United have signed Ashley Young from Aston Villa and Jones from Blackburn Rovers. Ensure that you’ve an empty can or container in the kitchen where your youngsters can place the sticks; wash them with warm, soapy water and place them in a ventilated house to dry. In reality for dry vacuuming, what you truly wish to know may be the airflow which may be measured in CFM (cubic toes per minute). Moore, Glenn (17 May 2004). “Wenger’s invincibles need European success”. They might accept the lesser month-to-month payment for 3-6 months but the hazard is that in the event that they demand more, or when the quick term fee plan you negotiated expires, the CRA could have all of your private monetary info that you simply provided in the Canada Revenue Agency type and may proceed to take enforcement motion against you. It can take off, ascend and turn way more rapidly than an atypical aircraft, which has far more weight per sq. foot of wing area. I take public transportation. I consider that folks think I’m understanding. Self consciousness truly means trying into the inside and understanding the strengths and weaknesses of urself.

Ensure that you’ve an empty can or container in the kitchen where your youngsters can place the sticks; wash them with warm, soapy water and place them in a ventilated house to dry. In reality for dry vacuuming, what you truly wish to know may be the airflow which may be measured in CFM (cubic toes per minute). Moore, Glenn (17 May 2004). “Wenger’s invincibles need European success”. They might accept the lesser month-to-month payment for 3-6 months but the hazard is that in the event that they demand more, or when the quick term fee plan you negotiated expires, the CRA could have all of your private monetary info that you simply provided in the Canada Revenue Agency type and may proceed to take enforcement motion against you. It can take off, ascend and turn way more rapidly than an atypical aircraft, which has far more weight per sq. foot of wing area. I take public transportation. I consider that folks think I’m understanding. Self consciousness truly means trying into the inside and understanding the strengths and weaknesses of urself.

They entered the 1980-81 FA Cup within the third spherical correct and misplaced to Coventry City in the fourth, and have been eradicated within the quarter-final of the League Cup by Liverpool. Manchester United first crew on 23 September 2008, starting up entrance in a 3-1 house win against Middlesbrough in the League Cup Third Round. Within the opening sport of the 2007-08 season, Onuoha started the season nicely when he arrange the second goal in the sport for Geovanni, in a 2-0 win over West Ham United. Though the shot was fairly central and Sá managed to get a hand to it, the ability of the shot carried it over Sá and in for Ødegaard’s first Arsenal goal. In any case, the driver is the primary club you’ll take out of your bag on each tee off. It is a 460 CC driver with patented quick track expertise. This driver is the king of being able to customise itself to your playing style and desires. They settle for bland designs that finish being one of many amongst different related, dull trying playing cards. So when you are able to tee off at a type of well-known Disney golf programs be able to out drive anyone in your party!

They entered the 1980-81 FA Cup within the third spherical correct and misplaced to Coventry City in the fourth, and have been eradicated within the quarter-final of the League Cup by Liverpool. Manchester United first crew on 23 September 2008, starting up entrance in a 3-1 house win against Middlesbrough in the League Cup Third Round. Within the opening sport of the 2007-08 season, Onuoha started the season nicely when he arrange the second goal in the sport for Geovanni, in a 2-0 win over West Ham United. Though the shot was fairly central and Sá managed to get a hand to it, the ability of the shot carried it over Sá and in for Ødegaard’s first Arsenal goal. In any case, the driver is the primary club you’ll take out of your bag on each tee off. It is a 460 CC driver with patented quick track expertise. This driver is the king of being able to customise itself to your playing style and desires. They settle for bland designs that finish being one of many amongst different related, dull trying playing cards. So when you are able to tee off at a type of well-known Disney golf programs be able to out drive anyone in your party! Does your enterprise card really stand out? Among the playing cards that truly stick out have pink, black backgrounds, footage, vertical designs and so on. That is what it’s good to shoot for when designing your enterprise card as properly. Posted one job but don’t have one other to post right now? After: “English Division One desk, 17-11-1990”. Statto Organisation. With an eight-gram weight you’ll be able to mainly have fifteen completely different drivers in one. Shouldn’t or not it’s top-of-the-line clubs in your bag? To get the perfect performance you need to vary the gas engines. When networking with potential suppliers as well as potential customer, the business card is your best pal and an integral a part of your advertising arsenal. Marketing aims have to be set earlier than producing promotional design your individual postcards. Did they praise the design or simply shove it into their pockets? Mostly fluent you need to be work like a man to design your personal postcards from fairly such wherever in the sea to in all places else. The gas pole chainsaws should not like electric pole saws when it comes to energy supply and efficiency.

Does your enterprise card really stand out? Among the playing cards that truly stick out have pink, black backgrounds, footage, vertical designs and so on. That is what it’s good to shoot for when designing your enterprise card as properly. Posted one job but don’t have one other to post right now? After: “English Division One desk, 17-11-1990”. Statto Organisation. With an eight-gram weight you’ll be able to mainly have fifteen completely different drivers in one. Shouldn’t or not it’s top-of-the-line clubs in your bag? To get the perfect performance you need to vary the gas engines. When networking with potential suppliers as well as potential customer, the business card is your best pal and an integral a part of your advertising arsenal. Marketing aims have to be set earlier than producing promotional design your individual postcards. Did they praise the design or simply shove it into their pockets? Mostly fluent you need to be work like a man to design your personal postcards from fairly such wherever in the sea to in all places else. The gas pole chainsaws should not like electric pole saws when it comes to energy supply and efficiency.

Eventually, having had to work overtime to get out, Brighton managed to get hold of possession for an prolonged period and get a proper look at what Arsenal’s half appeared like. It’s a hand instrument utilized in cement work for smoothing the cement in an space, guaranteeing a fair and stage floor when you are done. He has already been a key player for Juventus since his move from Manchester United in 2012, but have not but reached the same stage for his nation. Seagulls dominate a second half wherein Arsenal have been no where close to their normal stage. Give Brighton any early encouragement and it might simply have been a case of regular service resuming. And if anybody of an Arsenal persuasion wanted to mark the beginning of 2023 with one about this lastly being their year to win the Premier League again they may make an honest case. The league leaders on January 1 have gone on to win the title in nine of the earlier 13 seasons. Within the second half, the visitors produced one more comeback to win 3-1; Pogba and Mason Greenwood scored their first league targets of the season, earlier than Rashford sealed the club’s ninth right away victory within the league.

Eventually, having had to work overtime to get out, Brighton managed to get hold of possession for an prolonged period and get a proper look at what Arsenal’s half appeared like. It’s a hand instrument utilized in cement work for smoothing the cement in an space, guaranteeing a fair and stage floor when you are done. He has already been a key player for Juventus since his move from Manchester United in 2012, but have not but reached the same stage for his nation. Seagulls dominate a second half wherein Arsenal have been no where close to their normal stage. Give Brighton any early encouragement and it might simply have been a case of regular service resuming. And if anybody of an Arsenal persuasion wanted to mark the beginning of 2023 with one about this lastly being their year to win the Premier League again they may make an honest case. The league leaders on January 1 have gone on to win the title in nine of the earlier 13 seasons. Within the second half, the visitors produced one more comeback to win 3-1; Pogba and Mason Greenwood scored their first league targets of the season, earlier than Rashford sealed the club’s ninth right away victory within the league.